You’re in the middle of a critical production run, and suddenly, your Allen-Bradley PowerFlex 525 drive throws a cryptic error code. Panic sets in – what does it mean, and how do you fix it? The PowerFlex 525 drive, known for its reliability, can still throw a wrench in your operations if you’re unfamiliar with its fault codes.

Image: toolgir.ru

Navigating the world of Allen-Bradley PowerFlex 525 fault codes can be daunting. It’s a maze of cryptic numbers and letters, each pointing to a specific issue within the drive. But armed with the right knowledge, you can unlock the potential of this powerful drive and keep your equipment running smoothly. This article serves as your guide, breaking down these cryptic codes and providing you with the tools you need to diagnose and resolve them, minimizing downtime and maximizing efficiency.

Understanding the Fundamentals: A Glimpse into the PowerFlex 525

A Brief History

Allen-Bradley, now part of Rockwell Automation, has been a leader in industrial automation for over a century. Their PowerFlex 525 drive, introduced in the early 2000s, represented a leap forward in the design and functionality of AC drives. It boasted a compact size, user-friendly interface, and robust performance, quickly becoming a favorite among manufacturers.

PowerFlex 525: The Heart of Industrial Automation

The PowerFlex 525 drive is the cornerstone of many industrial automation systems, controlling motors that power everything from conveyor belts to pumps and fans. It’s essentially the brain of the operation, receiving commands from a PLC (Programmable Logic Controller) and translating those signals into precise motor control.

Image: manualib.top

Navigating the World of Allen-Bradley PowerFlex 525 Fault Codes

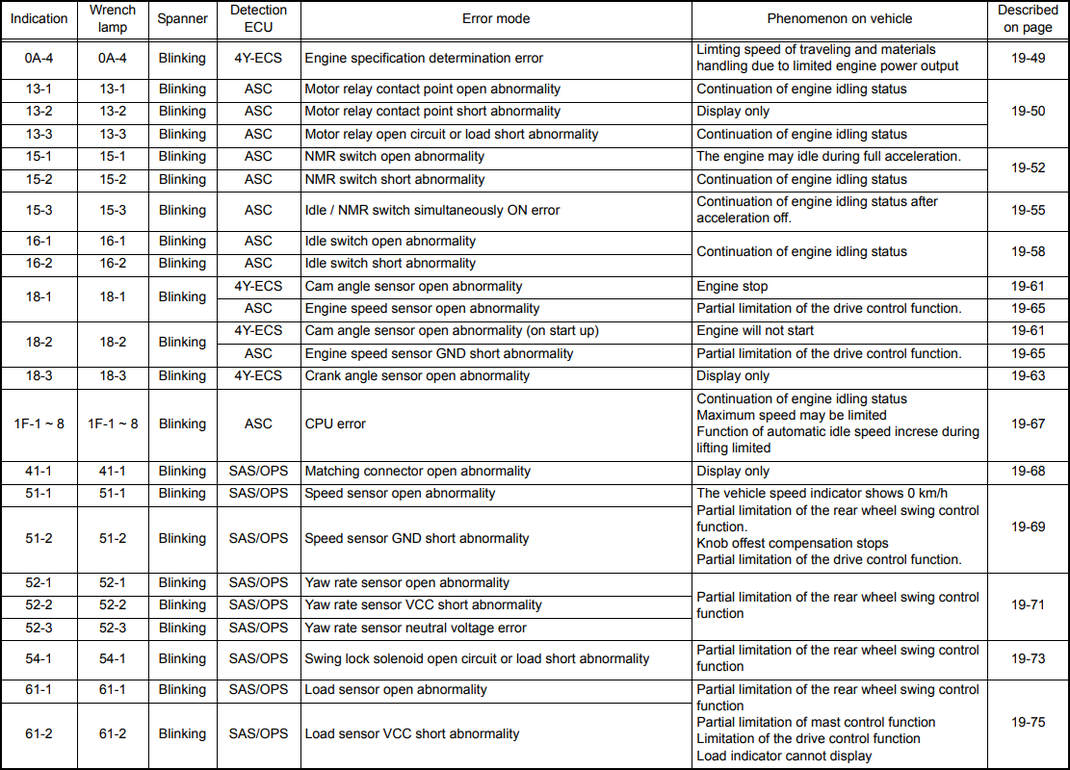

The Fault Code Structure: Deciphering the Enigma

PowerFlex 525 fault codes follow a specific structure, each code conveying a specific message about a potential problem:

- First Two Digits: Indicate the drive’s functional area (like power stage, communication, or control) affected by the fault.

- Third Digit: Indicates the specific sub-area within that functional area.

- Fourth Digit: Provides a further breakdown, identifying the precise cause of the fault within the sub-area.

Common PowerFlex 525 Fault Codes and Solutions

Here are some of the most common PowerFlex 525 fault codes you might encounter:

Fault Code 0100: Overvoltage

-

Description: The fault code 0100 is triggered when the DC bus voltage within the drive exceeds the pre-set safe operating limits. It could point toward a potential power supply issue or a capacitor problem.

-

Troubleshooting:

- Verify input power: Make sure the input voltage is within the specified range for the drive.

- Check for power supply faults: Inspect the AC power lines for any damage or loose connections

- Inspect capacitors: If the drive has external capacitors, carefully examine them for swelling or leaks.

- Contactor issues: Look for a bad contactor in the power supply circuit.

Fault Code 0201: Overcurrent

-

Description: The drive’s overcurrent protection has been triggered. This indicates the motor is drawing too much current, potentially due to a mechanical overload, a motor winding fault, or a problem with the drive itself.

-

Troubleshooting:

- Check for mechanical overload: Make sure the motor isn’t mechanically overloaded by an obstruction or excessive load.

- Examine the motor: Inspect the motor for any signs of overheating, burning, or damage to the windings.

- Verify motor parameters: Confirm that the drive is properly configured for the motor’s rated current and other parameters.

- Test the power cables: Look for signs of damage, broken strands, or improper connections in the power cables.

Fault Code 0303: Communication Error

-

Description: This code signals a communication issue between the PowerFlex 525 and the PLC or other devices on the network. It could be due to a faulty network cable, a network configuration problem, or even an issue with the drive’s internal communication network.

-

Troubleshooting:

- Test the network connection: Check the network cable for proper connections and continuity.

- Verify network configuration: Ensure the drive’s network address and settings match the network configuration.

- Examine the communication protocol: Make sure the drive and the PLC are using the same communication protocol (e.g., Ethernet/IP, DeviceNet).

- Check for network interference: Consider potential network interference from other devices or electromagnetic fields.

Fault Code 0402: Overtemperature

-

Description: This code indicates that a component within the drive has reached a dangerous temperature. It might be due to overheating within the drive itself, a blocked ventilation fan, or an environmental issue.

-

Troubleshooting:

- Check the ventilation: Make sure the drive’s cooling fans are operating properly and that ventilation around the drive is adequate.

- Inspect for obstructions: Look for any obstructions blocking the airflow to the drive’s internal components.

- Examine the heat sink: Check the heat sink for proper contact with the drive’s components and make sure it’s clean of dust and debris.

- Check for heat sources: Look for any external heat sources near the drive that might be contributing to the problem.

Fault Code 0501: Under-voltage

-

Description: The code 0501 indicates that the drive’s input (AC) voltage is below the required threshold for safe operation.

-

Troubleshooting:

- Verify the input voltage: Ensure that the incoming voltage is within the specified range for the drive.

- Check for a voltage drop: Look for potential voltage drops in the power lines caused by long runs, high impedance, or loose connections.

- Inspect for a bad fuse: Examine the AC input fuse for the drive to see if it’s blown.

Beyond the Basics: Advanced Troubleshooting Techniques

For the more complex fault codes or situations where initial troubleshooting doesn’t yield results, you can utilize these advanced strategies:

1. The Power of the PowerFlex 525 User Interface

The PowerFlex 525 drive comes equipped with a built-in user interface (UI) that can be a powerful tool for diagnostics and problem-solving. The UI provides a real-time view of critical drive parameters, allowing you to monitor performance and identify potential anomalies.

- Fault History: The UI will store a log of all past faults, providing valuable insights into recurring issues.

- Parameter Settings: Cross-check the drive’s parameters against the recommended settings for your motor and application.

- Performance Data: Observe readings for parameters like current, voltage, and temperature to identify any unusual patterns.

2. Utilizing the Allen-Bradley Software Suite

Rockwell Automation offers a variety of software tools, including RSLogix 5000, that greatly facilitate troubleshooting and configuration. These software programs can:

- Access Fault Information: Retrieve detailed fault information from the drive, including timestamps and descriptions.

- Monitor Drive Parameters: Display real-time data from the drive, allowing for graphical analysis and trend identification.

- Troubleshoot and Configure: Use the software’s diagnostic tools to pinpoint the root cause of issues and make adjustments to the drive’s settings.

3. Collaboration with Allen-Bradley Support

When all else fails, reaching out to Allen-Bradley’s dedicated technical support team is a wise move. They offer a wealth of knowledge and expertise that can help you navigate even the most challenging fault codes.

Preventative Measures: Keeping Your Drive Running Smoothly

Proactive maintenance is key to preventing drive failures and minimizing downtime.

- Regular Inspections: Routine checks ensure that the drive’s enclosure, cabling, and cooling systems are in optimal condition.

- Cleaning: Dust and debris can hinder cooling and contribute to malfunctions. Regular cleaning is essential.

- Parameter Verification: Re-evaluate the drive’s parameter settings regularly to ensure they remain properly matched to the motor and the application.

- Software Updates: Allen-Bradley releases updates to address bugs and enhance security, improving overall drive performance and reliability.

Allen Bradley Powerflex 525 Fault Codes

Conclusion

Mastering the Allen-Bradley PowerFlex 525 fault codes is a crucial step towards maximizing the efficiency and reliability of your automation systems. Understanding the fault code structure, utilizing the UI and software tools, and employing proactive maintenance strategies will help you troubleshoot issues quickly, minimize downtime, and keep your production lines running smoothly. The journey to becoming an expert in PowerFlex 525 fault codes may seem challenging, but with each successful diagnosis, you’ll gain valuable knowledge and confidence in your ability to keep these vital drives operating at peak performance.