The engine hums, the road stretches before you, and the weight of a thousand dreams rests on your shoulders. Life on the road is a symphony of rumbling engines, shifting gears, and the constant whisper of the wind. But sometimes, the symphony falls silent, replaced by a jolting beep, a flashing light, and a cold dread crawling up your spine. A “Sensor Supply Voltage 5” error can throw the most seasoned trucker for a loop, leaving you stranded on the side of the road with a heart full of frustration and a mind racing with questions: What does it mean? Where is this mysterious sensor located? How do I fix it? Fear not! This article is your guide to navigating the treacherous terrain of this common Cummins ISX engine code, equipping you with the knowledge to understand, troubleshoot, and conquer this pesky error.

Image: mydiagram.online

The “Sensor Supply Voltage 5” code in your Cummins ISX engine is not just a cryptic message – it’s a beacon pointing to a potential malfunction in a vital component of your truck’s electronic network. This sensor is essentially the eyes and ears of your engine, feeding life-critical data back to the control module—telling it everything from the air pressure in your intake manifold to the temperature of your engine coolant. Without this information, your engine wouldn’t know how to breathe, how much fuel to inject, or even when to shift gears. A faulty sensor can lead to decreased fuel efficiency, sluggish performance, or even complete engine shutdowns, leaving you stranded and your delivery dreams scattered like fallen leaves in the wind.

Diving Deeper: Unveiling the Mystery of Sensor Supply Voltage 5

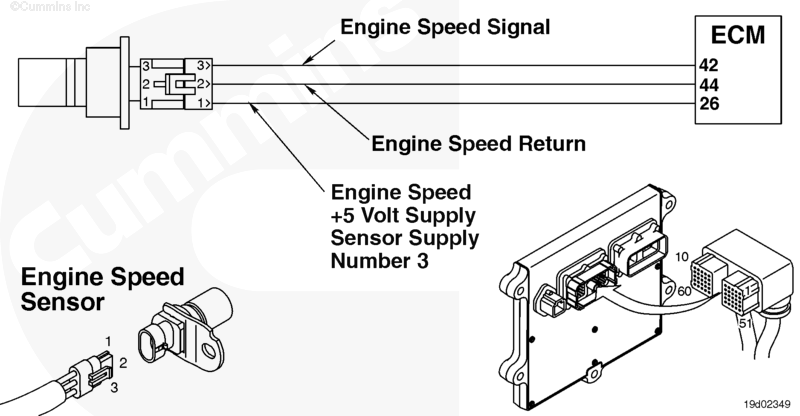

To understand the “Sensor Supply Voltage 5” code, we must first understand the intricate ecosystem of sensors that govern the lifeblood of your ISX engine. These sensors, each a silent guardian of your truck’s well-being, operate through a delicate dance of electricity. Each sensor requires a specific voltage to function correctly, ensuring accurate data transmission to the engine control module (ECM). The “Sensor Supply Voltage 5” code signals that a particular sensor is not receiving the correct voltage, interrupting its communication with the ECM. This voltage deficit can stem from a variety of sources, including a faulty sensor, a broken wire, a damaged connector, or even a malfunctioning ECM itself.

The Clues: Pinpointing the Problem

The dreaded “Sensor Supply Voltage 5” message can be a frustrating mystery, leaving you staring at your dashboard like it’s a cryptic oracle. But fret not! There are clues you can use to unravel this puzzle. The first step is to consult your Cummins ISX engine repair manual, the user’s bible for all your troubleshooting needs. This manual will typically list the exact location of the culprit sensor, giving you a starting point for your investigation. For instance, the “Sensor Supply Voltage 5” code could indicate a faulty coolant temperature sensor, a temperamental air intake manifold pressure sensor, or a rogue fuel pressure sensor.

A Sherlockian Approach: Decoding the Symptoms

You may not be Sherlock Holmes, but by closely observing your truck’s behavior, you can piece together valuable clues about the culprit sensor. Is your engine struggling to start? A faulty coolant temperature sensor might be to blame, as it plays a critical role in determining the engine’s starting parameters. Are you experiencing rough idling or unexpected engine shutdowns? A malfunctioning fuel pressure sensor could be the instigator, as it monitors the fuel pressure delivered to your engine. Each sensor is responsible for a specific aspect of your engine’s operation, and the symptoms of their malfunction are often like fingerprints, unique and traceable.

Image: www.blog-teknisi.com

Tools of the Trade: Diagnosing the Issue

With the symptoms in hand and the sensor’s location pinpointed, you’re ready to delve into the realm of diagnostics. You’ll need a few tools to embark on this journey:

- A multimeter: This versatile tool allows you to measure voltage and resistance, helping you confirm whether the sensor is receiving the proper power and transmitting data accurately.

- A wiring diagram: The Cummins ISX engine is a complex machine with a labyrinthine wiring system. This diagram will be your map, guiding you through the electrical pathways and helping you identify potential breaks, shorts, or loose connections.

- A spare sensor (optional): If you suspect the sensor itself is faulty, having a spare on hand allows you to quickly replace it and test its functionality.

The Investigation: Seeking the Culprit

Now, with your tools in hand, you can embark on a meticulous investigation.

-

Check for loose connections: Start by inspecting the sensor connector for signs of corrosion, loose wires, or damage. A visual inspection can often reveal simple fixes.

-

Test the sensor’s voltage: Using your multimeter, measure the voltage at the sensor’s terminals. Refer to your repair manual to confirm the expected voltage, and if it falls short, you’ve identified a likely culprit.

-

Inspect the wiring: Trace the wiring back from the sensor to its source, looking for any signs of damage, breaks, or fraying.

-

Test for resistance: If you suspect the sensor itself is faulty, you can test its resistance using your multimeter. The repair manual will provide the expected resistance range for your sensor.

The Verdict: Fixing the Problem

Once you’ve identified the culprit – be it a faulty sensor, a damaged wire, or a loose connection – you’re ready to administer the remedy.

- Replace the sensor: If the sensor itself is defective, replace it with a new, compatible unit.

- Repair the wiring: If you discover a broken wire or a loose connection, repair or replace it using proper techniques.

- Check connector pins: Inspect the connector pins for signs of corrosion or damage. Clean them or replace the connector if necessary.

Expert Insights: Prevention is Key

Experienced truckers and seasoned mechanics often emphasize the importance of preventative maintenance.

- Regular inspections: Make it a habit to regularly check your sensors for signs of wear and tear.

- Clean connectors: Keep connectors clean and free of corrosion to ensure reliable electrical contact.

- Use quality parts: Invest in high-quality replacement parts to ensure longevity and optimal performance.

Sensor Supply Voltage 5 Cummins Isx Location

The Road Ahead: Empowered and Informed

By understanding the “Sensor Supply Voltage 5” code, you’ve gained the power to conquer this troublesome error and keep your Cummins ISX engine running smoothly. As you cruise down the highway, the rumble of your engine becomes a familiar lullaby, reminding you of the journeys you’ve conquered and the roads that lie ahead. The “Sensor Supply Voltage 5” code is no longer a daunting demon, but a familiar puzzle, waiting to be deciphered and overcome. Remember, knowledge is power, and in the world of trucking, that power empowers you to keep your truck rolling and your dreams on track.