Imagine you’re constructing a magnificent skyscraper. Every piece, from the foundation stones to the gleaming windows, must be meticulously planned and accounted for. The blueprint isn’t just a drawing; it’s a detailed list of every material needed, precisely measured and categorized. This, in essence, is the essence of a Bill of Materials (BOM). In the world of manufacturing, engineering, and construction, the BOM holds the key to turning dreams into reality, ensuring projects stay on track, within budget, and delivered with precision.

Image: studycampusmax.z19.web.core.windows.net

Unit 5 of any course, particularly one related to engineering or manufacturing, delves into the critical functions of a BOM. It’s not just about listing parts; it’s about understanding the intricate relationships between them, how they impact costs, and how they influence the entire project lifecycle. This article will guide you through the labyrinth of Unit 5 BOM answers, unveiling the secrets of this powerful tool and empowering you to build your own successful ventures.

The Foundation: What is a BOM?

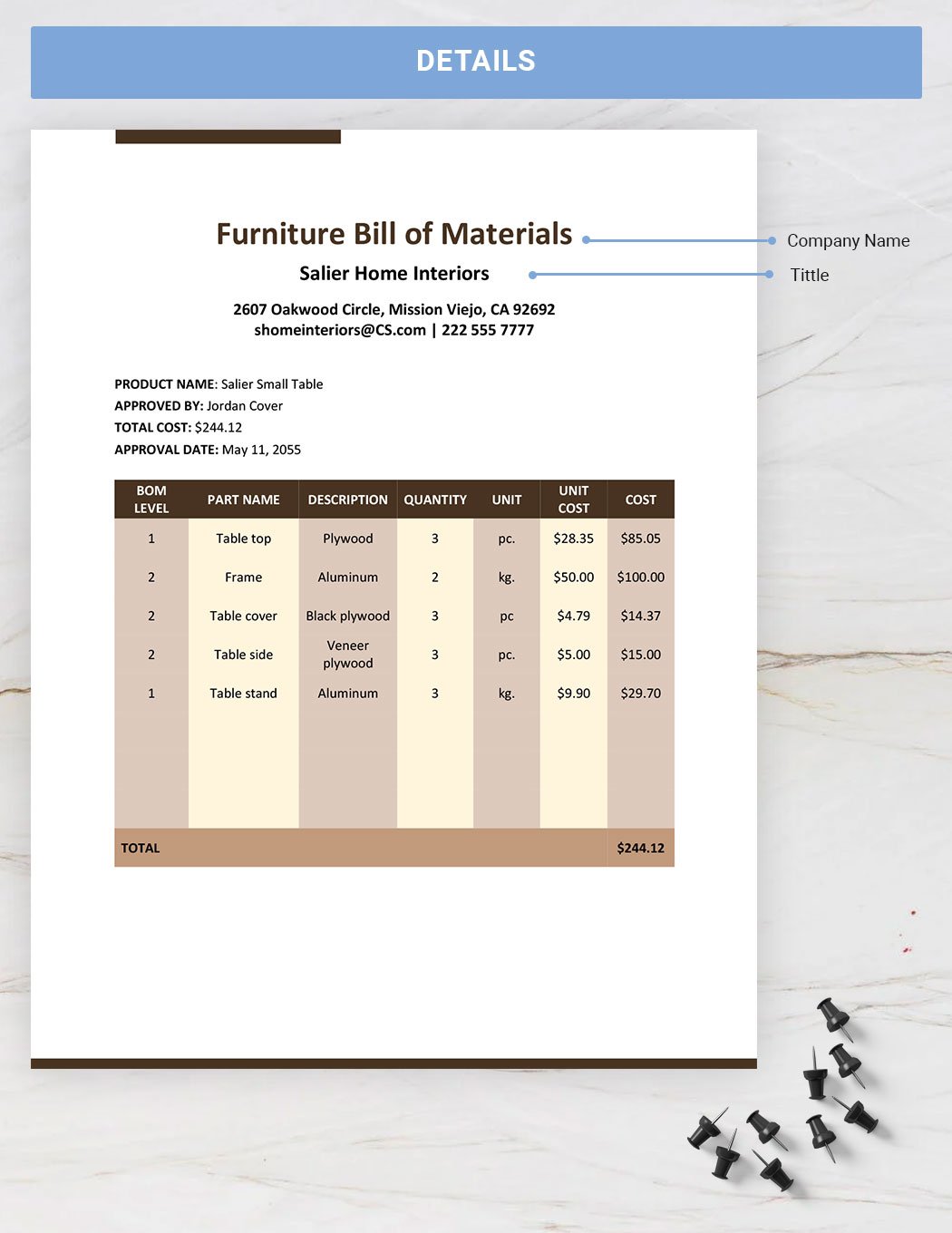

At its heart, a BOM is a comprehensive list of all the components, parts, and materials required to build a particular product. Think of it as a shopping list for a complex creation. But unlike a simple shopping list, a BOM goes beyond mere quantities; it also encompasses essential details:

- Part Numbers: Each component is assigned a unique identifier for easy tracking.

- Descriptions: Clear and concise descriptions ensure everyone understands what the part is.

- Quantities: The exact number of each part needed is specified to ensure accurate ordering and inventory management.

- Units of Measure: From meters to kilograms, each component’s quantity is expressed in its appropriate unit.

- Specifications: Detailed specifications like dimensions, materials, and tolerances guarantee uniformity and consistency in production.

- Revisions: BOMs are living documents that evolve as designs change. Each revision must be carefully documented to ensure everyone is working with the latest version.

Navigating the BOM Labyrinth: Types and Structures

BOMs are not one-size-fits-all. Different industries and projects require different structures and classifications. Understanding these variations is crucial for achieving optimal efficiency. Here are some key types:

- Single-Level BOM: This simplest form lists all components directly under the main product. Think of it as a hierarchical structure with only one layer.

- Multi-Level BOM: This type allows for complex assemblies where components may be further broken down into sub-assemblies. Think of it as a tree with multiple branches, where each branch represents a subassembly.

- Indented BOM: This type utilizes indentation to indicate the hierarchy of components. The further indented a component is, the lower its level in the assembly. This structure aids in visual clarity.

- Exploded View BOM: This type uses a visual representation of the product, with each component labeled and referenced to the BOM. This offers a powerful understanding of the product’s assembly process.

Building Success with BOM: Key Applications

The power of the BOM extends far beyond just listing parts. Understanding its diverse applications reveals its true value:

- Engineering and Design: BOMs act as blueprints, guiding designers and engineers in creating innovative products. They ensure that every element integrates seamlessly, creating a cohesive whole.

- Manufacturing: BOMs empower manufacturers to order the right parts in the right quantities, ensuring smooth production line operation and minimizing waste. They also aid in inventory management and scheduling.

- Cost Estimation: BOMs are fundamental to accurate cost estimation. By analyzing component costs, manufacturers can predict total project costs with greater precision.

- Quality Control: BOMs provide a comprehensive reference point for quality control processes. They ensure that the correct materials are used and that components meet specified tolerances, contributing to product reliability.

- Supply Chain Management: BOMs are crucial to managing intricate supply chains. They facilitate communication with suppliers, enabling efficient sourcing and fulfillment of materials.

Image: www.sexizpix.com

Turning BOM Wisdom into Action: Best Practices and Tips

Armed with the knowledge of what a BOM is and its various applications, you can now leverage it for your success. Here are some practical tips to ensure you’re maximizing the power of this tool:

- Stay Organized: Employ structured tables, spreadsheets, or specialized software to manage BOM data efficiently. This makes it easy to access, modify, and share information.

- Embrace Standardization: Implementing standardized part numbers and descriptions across different projects allows for consistency and ease of comparison.

- Utilize Visual Aids: Combine your BOMs with visual representations (diagrams, exploded views) to provide a comprehensive understanding of the product.

- Be Specific: Avoid ambiguities. Clearly define each component’s specifications and tolerances to minimize errors in production.

- Embrace Collaboration: Foster communication between engineering, manufacturing, and purchasing teams to ensure everyone is working from the same BOM and addressing potential issues promptly.

The Future of BOM: Innovation and Automation

As technology continues to evolve, BOMs are becoming increasingly integrated with digital workflows and data management systems. These advancements are driving significant improvements in efficiency:

- Cloud-Based Platforms: Web-based BOM management systems offer real-time collaboration across geographically dispersed teams, streamlining communication and data sharing.

- Automated BOM Generation: Advanced software can automatically generate BOMs from 3D CAD models, reducing the potential for human error and expediting the design process.

- Data Analytics and Optimization: Integrated data analysis tools enable manufacturers to track cost variations, identify bottlenecks, and optimize material sourcing strategies.

Unit 5 Bill Of Materials Answers

The Path to Success: Building with Confidence

The Unit 5 journey into the realm of BOMs is a journey of learning and growth. It empowers you to understand the fundamental principles of manufacturing, engineering, and project management. By mastering the nuances of BOM creation, organization, and utilization, you equip yourself with the tools to build successful products, navigate complex projects, and confidently lead in your chosen field.

This knowledge is not just for engineers and manufacturers; it’s for anyone who wants to build anything, whether it’s a business, a team, or a creative project. The principles of planning, clarity, and precision that underpin the BOM transcend disciplines and provide a framework for success in any endeavor.